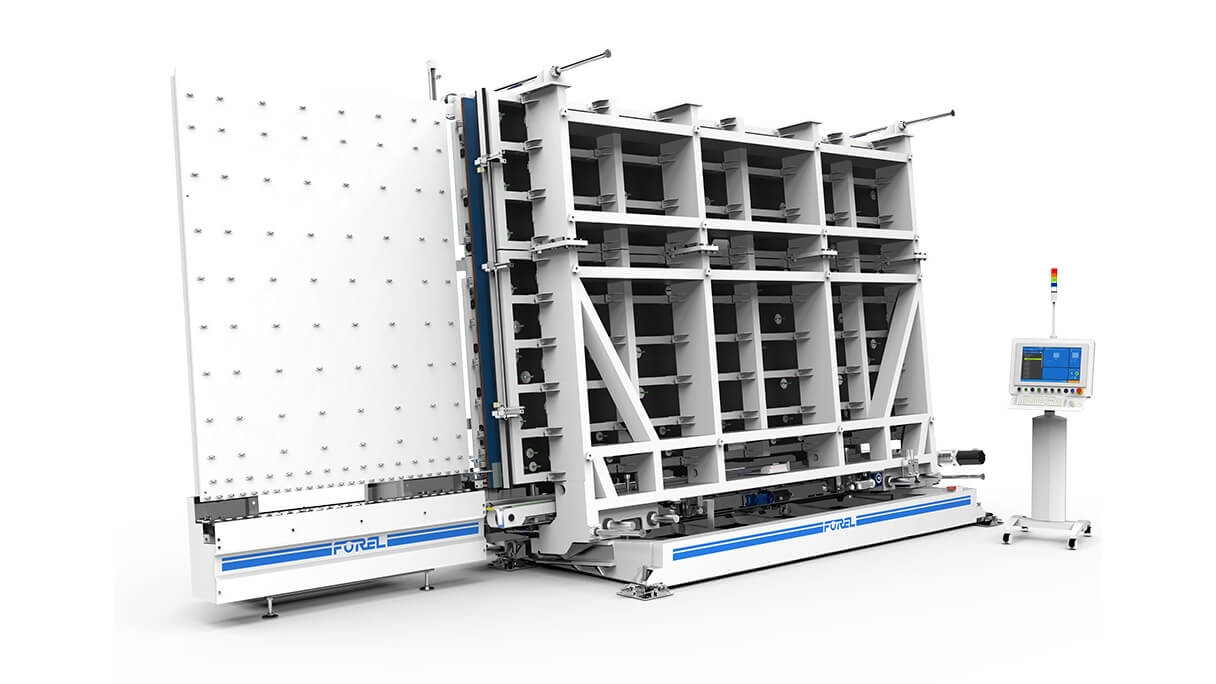

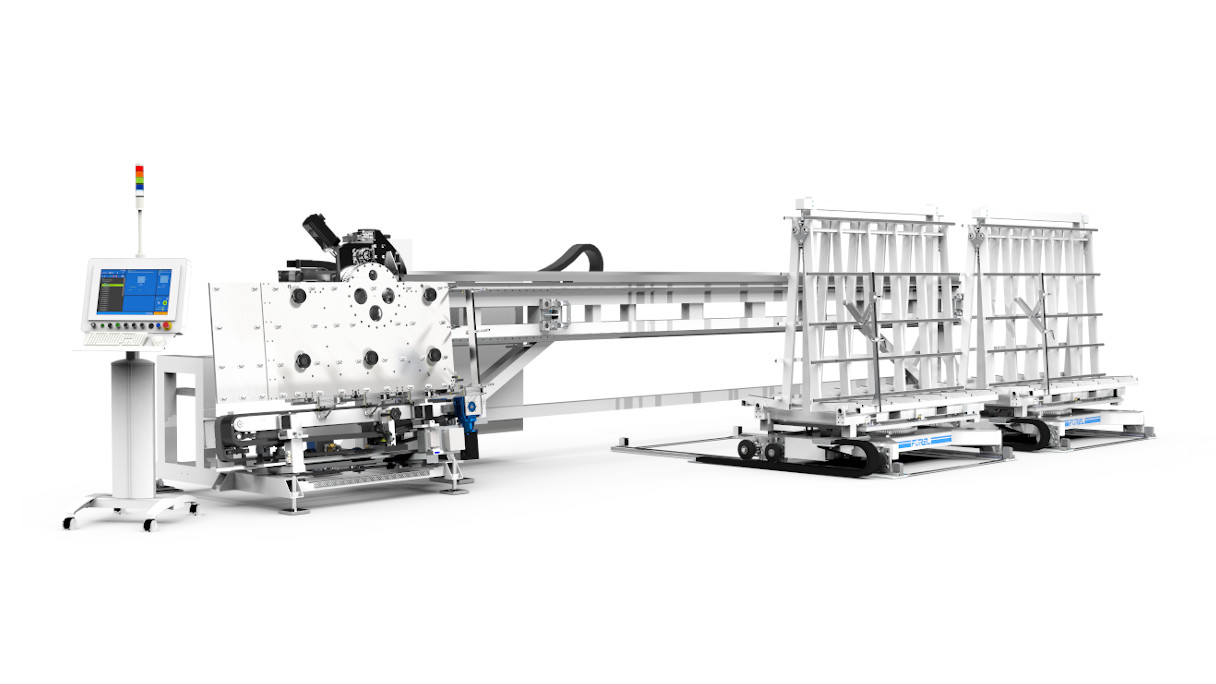

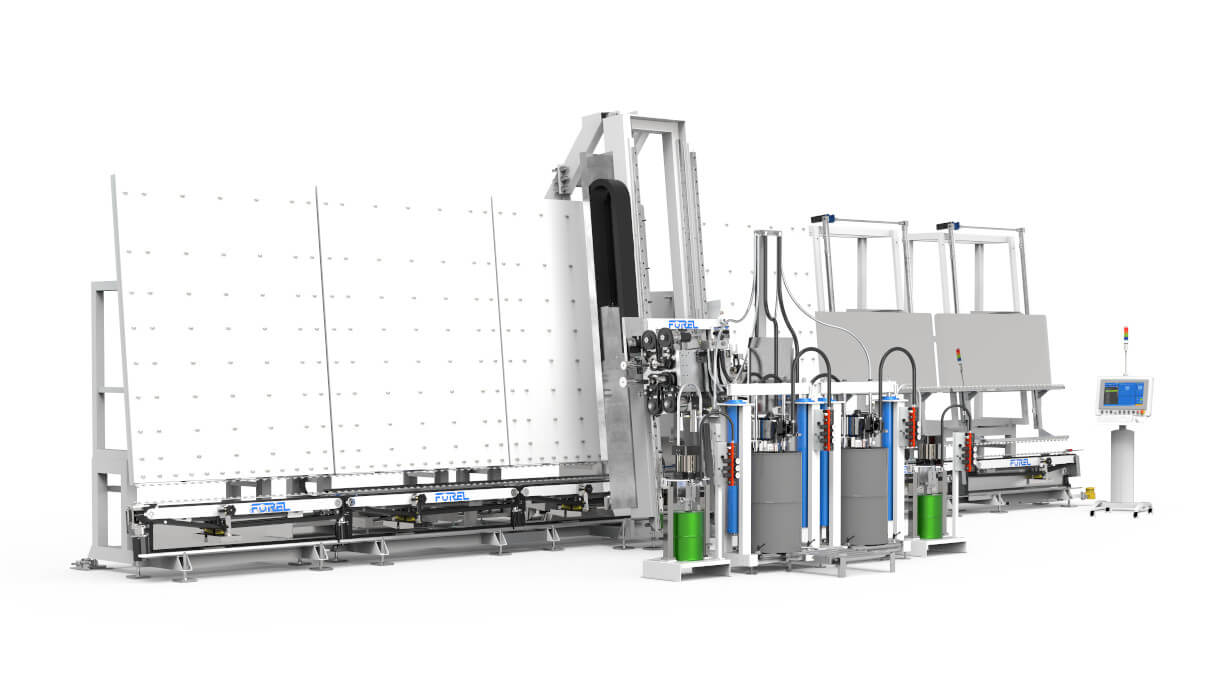

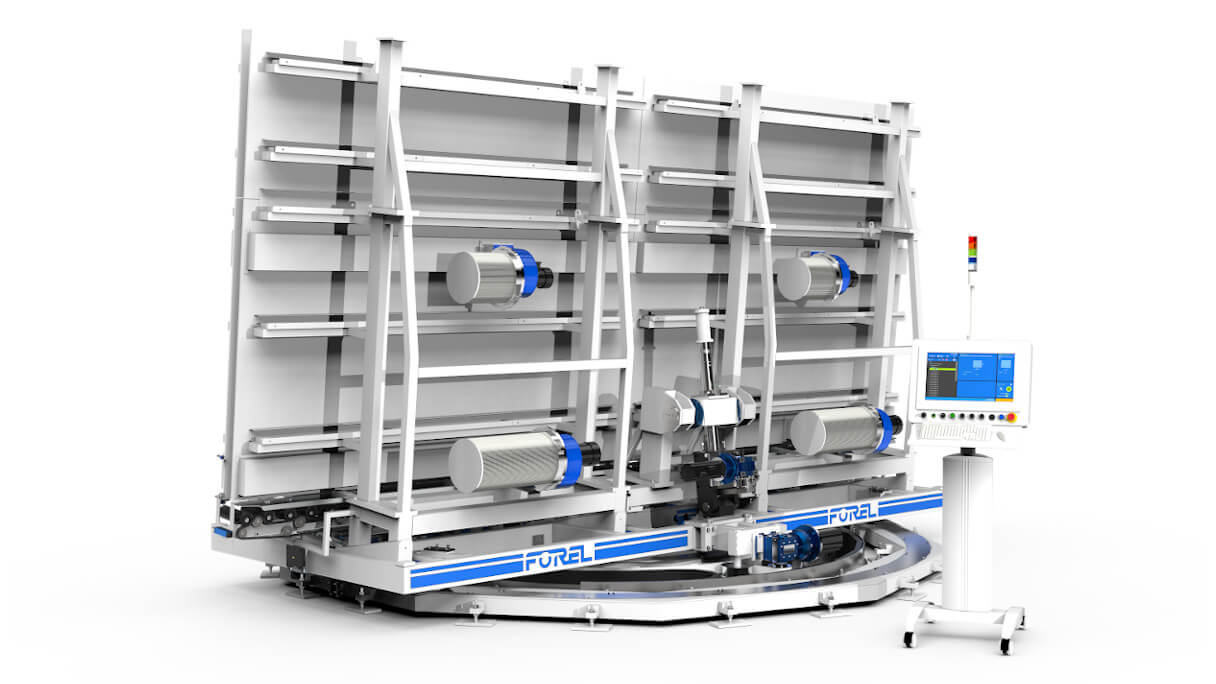

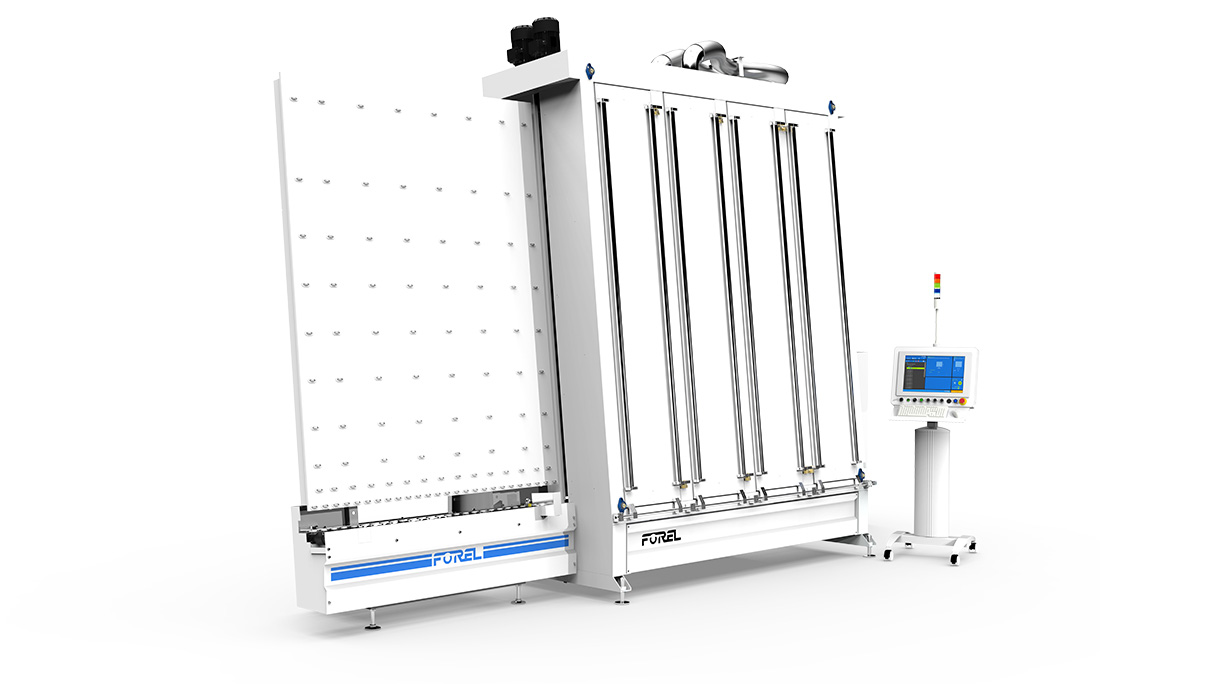

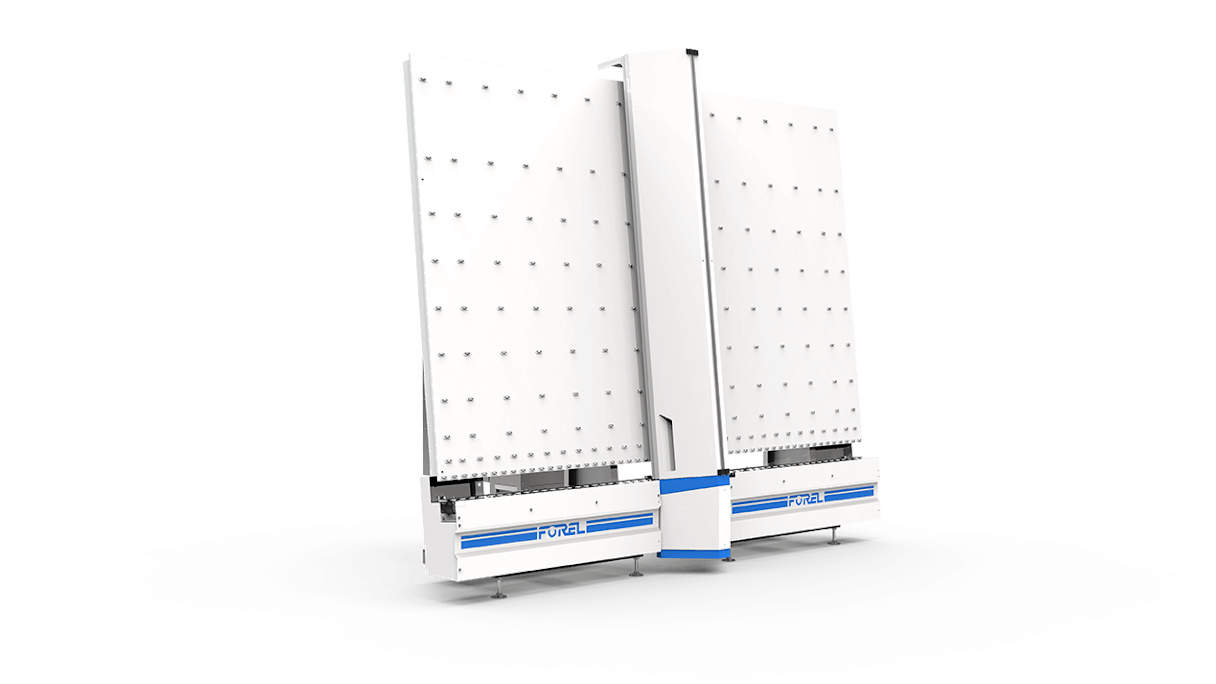

The Art. AT HT developed specifically for the accurate and seamless application of “T-Shape” flexible spacer. The flexible profile is stored on up to 4 reels within a hermetically controlled cabinet situated next to the applicator. The Art. AT HT is available in 4 models, to process IG units of up 6,000 x 3,300 mm. Art. AT automatically removes the protective film from the edges of the profile and infills the “T-Shaped” spacer with the measured amount of butyl pre glass application, in a non-stop extrusion system.

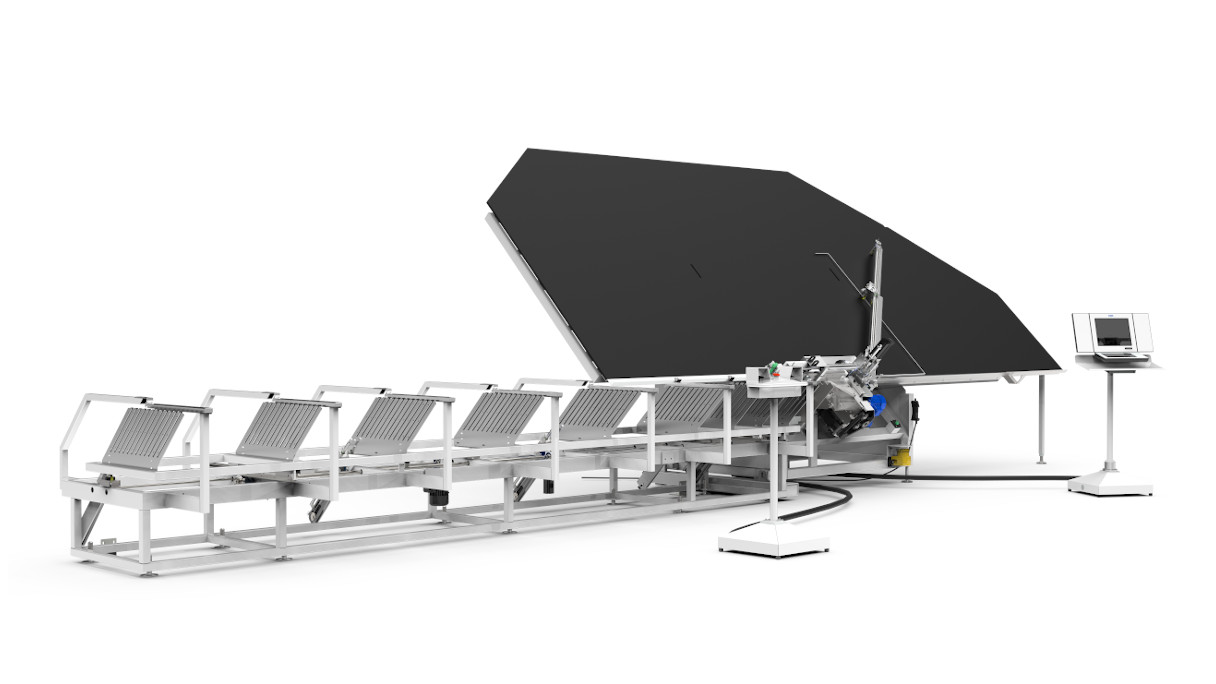

The profile buffer (patented) allows for continuous application of the spacer to the glass pane enhancing quality and overall output. Art. AT HT can process rectangular glass pieces automatically and shaped glass from file. Once the application process is completed, the final corner is closed by a Corner Tape applicator.