16.05.2025

Ravensby Glass is a glass company based in Dundee, Scotland, specializing in products such as double and triple glazed units, interior glass and facades. With over 150 employees and 7000 square meters of production space, the company distributes its products throughout the UK, distinguishing itself for quality, service and customer care.

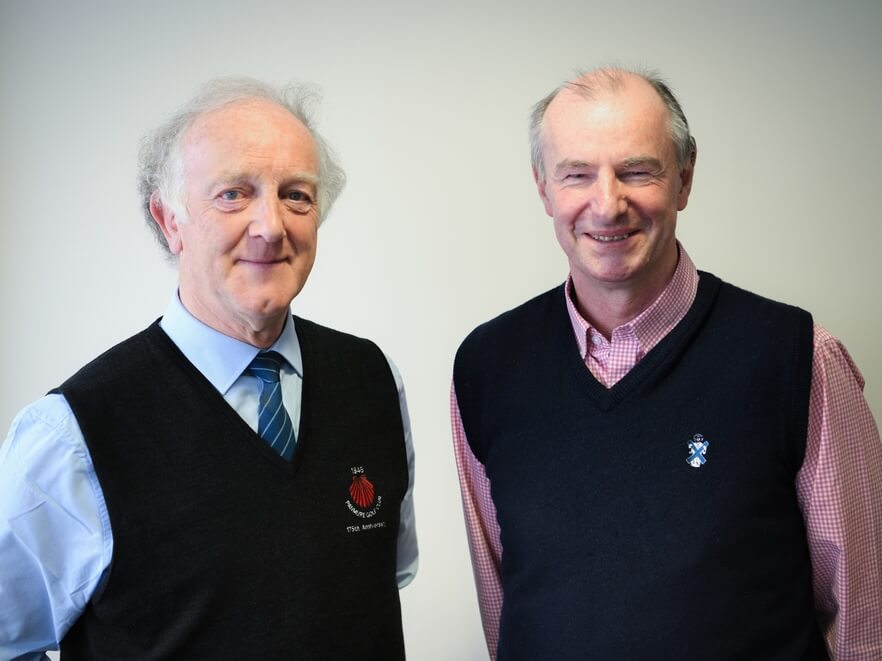

The history of Ravensby Glass has its roots in the 19th century, with the foundation of the group in 1847 of Malcolm, Ogilvie & Co. Ltd., at that time dedicated to textile manufacturing. Over the years, or rather decades, the group diversified its activities, investing in various businesses, reaching the glass sector in 1986 with the foundation of Ravensby Glass. A long history with one constant and unusual element: in over 160 years the ownership has remained intact. For five generations the founding families Ogilvie and Cunningham have run the group with passion and foresight, investing and evolving as the markets and opportunities dictated. We met the current owners: CEO Hamish Ogilvie and CFO Nicholas Cunningham, great-grandsons of the founders.

“After diversifying into different sectors, we have been in the glass business as processors since the 1980s» says Mr. Ogilvie «Over the years we have always invested in increasing the quality of our glass and the efficiency of our service. At our Tom Johnston Road site in Dundee where we have consolidated our activity for greater efficiency, we have created a hybrid plant dedicated to residential glass, which we distribute extensively in Scotland, and commercial glass, which we supply throughout the UK. We have put a lot of effort into having efficient logistics across such a large territory. In this latter regard, we have established a reputation as a reliable supplier, which is one of the company’s assets”.

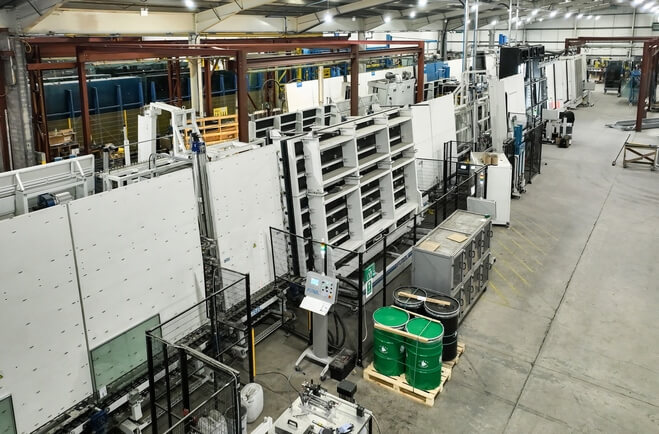

Ravensby Glass presents itself as a structured company. In the production plant, there are two warehouses of large panes, from which two horizontal cutting lines are fed. The glasses are then processed and tempered where needed, before being directed to one of three existing lines for the production of insulating glass.

“In 2019 we decided to enhance our production with a new insulating glass line» Mr. Ogilvie explains «and we accepted an invitation to visit the Forel plant in Italy. On this occasion we were very impressed by the technology and solutions developed, and decided to purchase our first Forel IGU Line along with a Vertical Processing Line, for the production of processed glass pre tempering. After overcoming the initial bedding in period of the new equipment (every machine of every brand has its own peculiarities) we were suitably satisfied with both lines’ performance, and as part of our growth strategy, we decided to order a second IGU line, to process projects related to both our residential and commercial sectors. Today these two Forel IGU Lines represent the core of our production and the Vertical Edging Line, processes the bulk of our glass production, an investment we are particularly satisfied with”.

The Forel machinery in operation at Ravensby Glass are; the “Residential” IG line, capable of processing double glazing units up to 4000 x 2500 mm, with rigid or flexible spacer bar, and a “High Tech” IG line with a wide range of options such as triple/quadruple glazing, all sides stepped and large piece processing of up to 5000 x 2800 mm. The edging machine is Forel Art. EM, appreciated worldwide and renowned for its precision and output performance in arrissing, grinding and polishing.

Like all manufacturing companies, Ravensby Glass faces the challenges of a competitive market in which new variables, such as rising energy costs and enhanced requirements for thermal performance have recently appeared.

“We are managing the complexities of this economic phase in different ways,» explains Mr. Cunningham «On the one hand, we have turned up the heat on our energy suppliers, particularly when our supply contract is expiring, and on the other hand we are rationalizing our production flow, for example by using only one toughening plant instead of two. This particular situation, however, does not change one basic reality: if the glass production is already highly automated today, it will have to be even more in the future. Forel’s system brings clear advantages in terms of productivity and allows for constant digital control over the work in progress, facilitating the operator’s task. This allows us to guarantee our customer the conformity of our product”.

Given its position in the UK market, Ravensby Glass has its finger on the pulse of both commercial and residential glass trends: two different realities that are reacting in different ways in this first half of 2023.

“Contrary to what might have been assumed a year ago, the demand for commercial glass shows no sign of contracting, quite the contrary” continues Mr. Ogilvie “The construction-architectural sector in the UK is in full swing and the need for facades, shopfronts and other installations will be a constant well into 2024. Despite the dampening effect we can expect due to the rising cost of raw materials, it is undeniable that there is a willingness to invest significantly in commercial glass, particularly triple glazing. In fact, in 2022, our orders were only 10% triple glazing, whereas today they are already 35%. As for the residential market, it is stable at the moment. However, I believe that the demand for triple glazing will also increase here before long, in the wake of what is happening in other sectors. From this point of view, Ravensby Glass is well prepared: when it comes to triple glazing, the Forel line has demonstrated really good performance”.