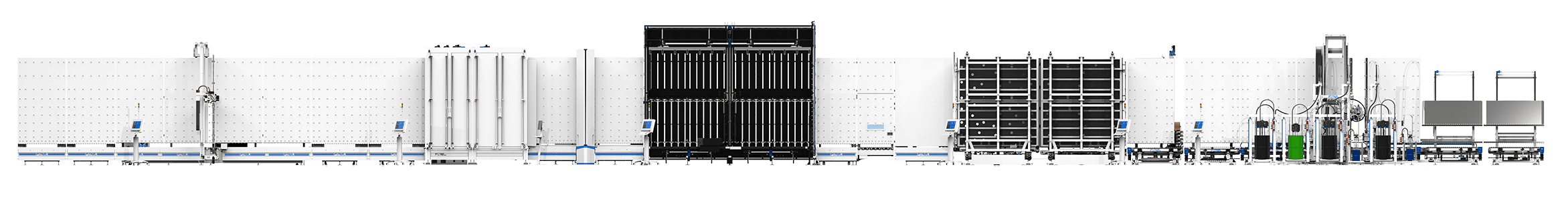

6000×3300 mm

9000×3300 mm

100 mm

550 kg

Line Server

Pane Curvature Management

Stepped units

Rigid/Flexible/Thermoplastic Spacer

Double/Triple/Quadruple Glazing

Argon/Krypton/Both Gas Filling

Up to 3 Sealing Products

Continous Sealing

Automatic Dosing Unit Change