Minimum glass thickness ( mm )

3

Maximum glass thickness ( mm )

21

Minimum length of glass / double glazing panel ( mm )

320

Minimum height of glass / double glazing panel ( mm )

180

Maximum length of glass / double glazing panel ( mm )

5000

Maximum height of glass / double glazing panel ( mm )

2800

Maximum transportable glass weight ( kg/ml )

200

Standard worktop height ( ± 20 mm )

640

Flexible spacer profile processing ( mm )

2850

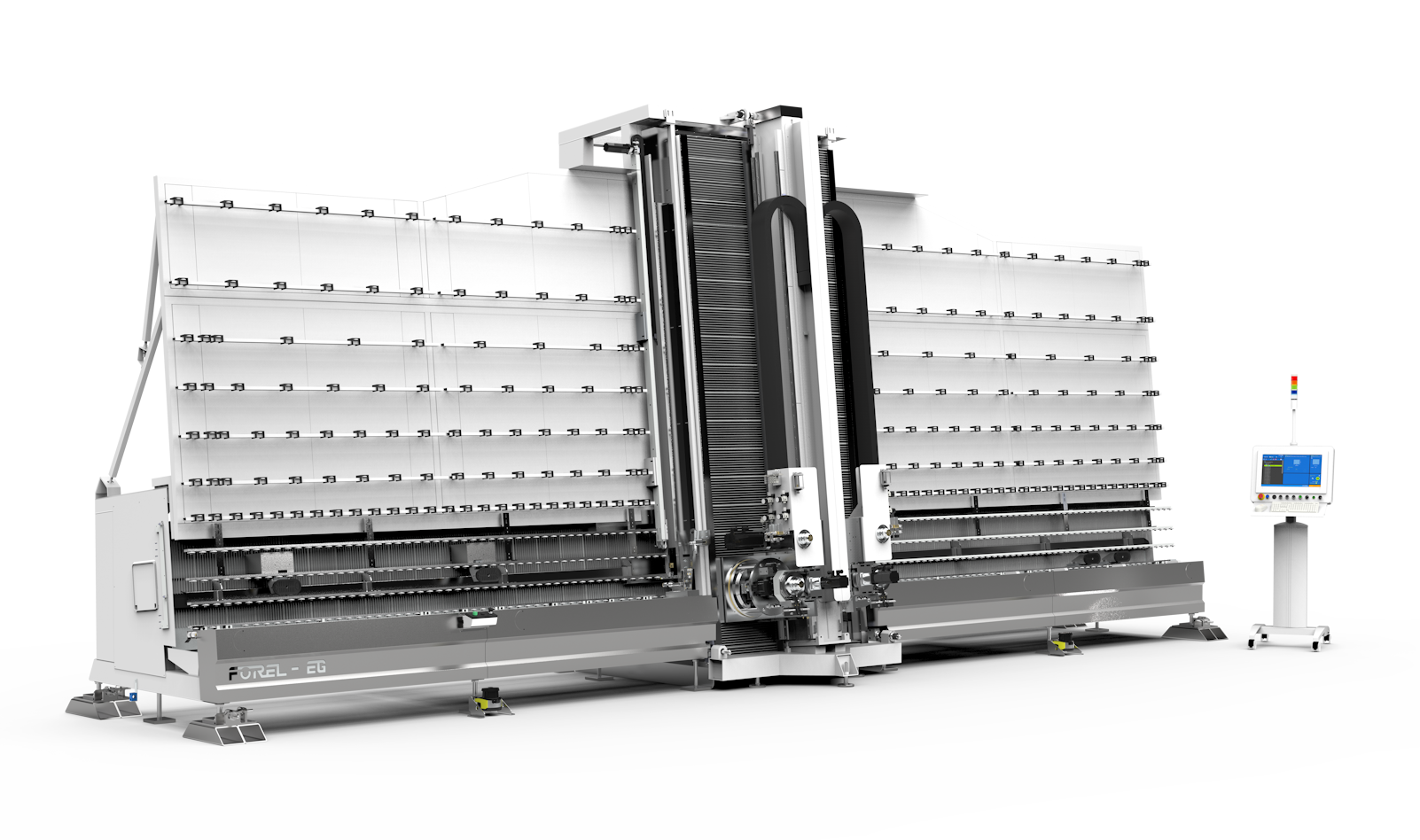

Overall height of the machine body ( mm )

4680

Overall length of the machine body in line ( mm )

11150