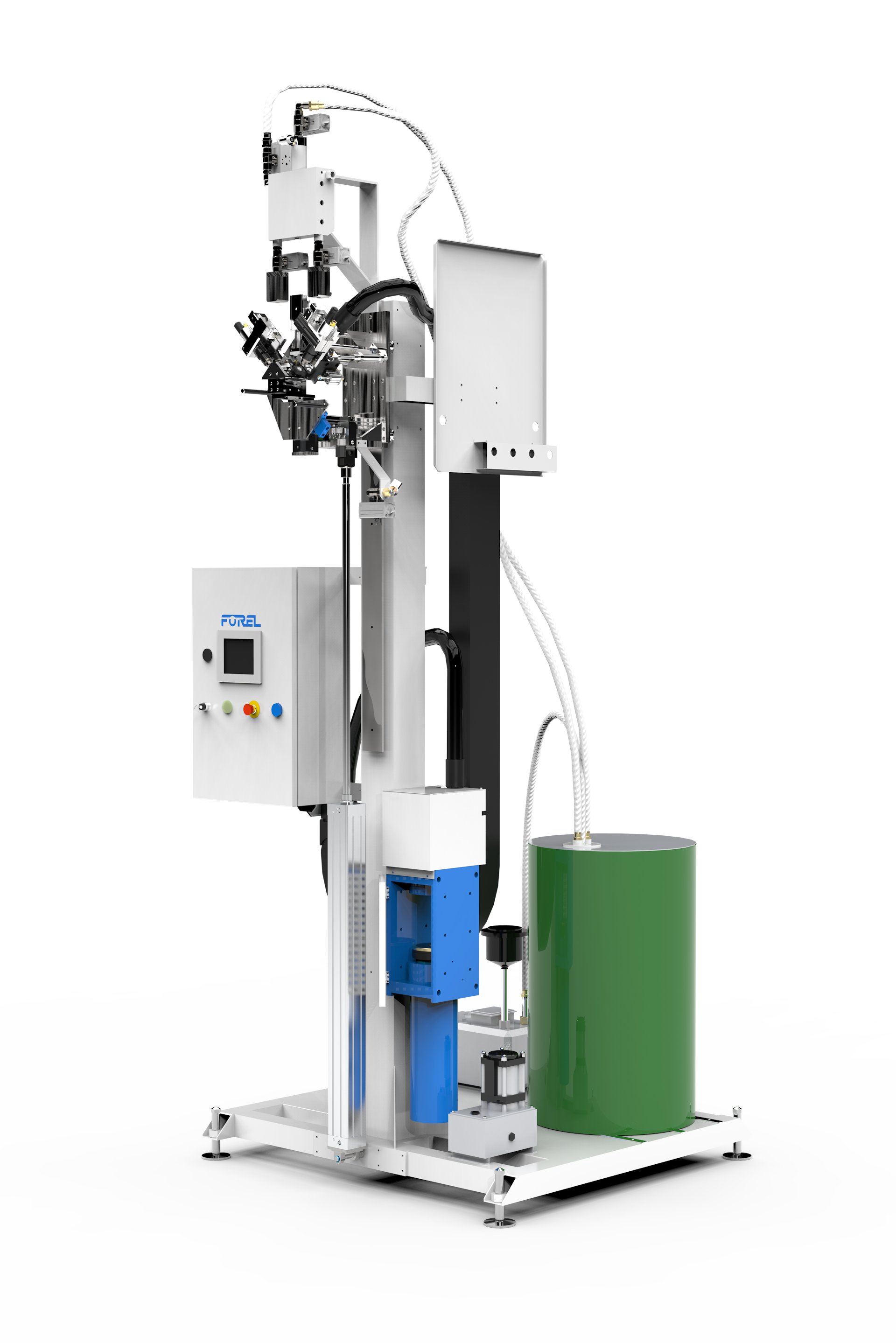

DF HT is a consolidated solution in the Forel product range for treating insulating glass spacers. This desiccant refill system integrates a precision structure with frame presser clamps and advanced drilling heads, for processing rectangular or shaped frames of any size. Able to drill and fill rigid spacers of different types and heights with hygroscopic material, DF HT is fundamental for preventing condensation inside insulating glass units. The machine stands out for the use of a vacuum pump to suction the desiccant from a 200 litre drum and for its shaped frame filling nozzle, as well as a pre-heating system for the butyl extrusion unit. With the additional option of automatic loading and unloading, DF HT turns spacer preparation into a quick, clean and fully automated process.