Minimum glass thickness ( mm )

3

Maximum glass thickness ( mm )

25

Maximum height of glass / double glazing panel ( mm )

2000

Maximum transportable glass weight ( kg/ml )

200

Standard worktop height ( ± 20 mm )

640

Flexible spacer profile processing ( mm )

1000

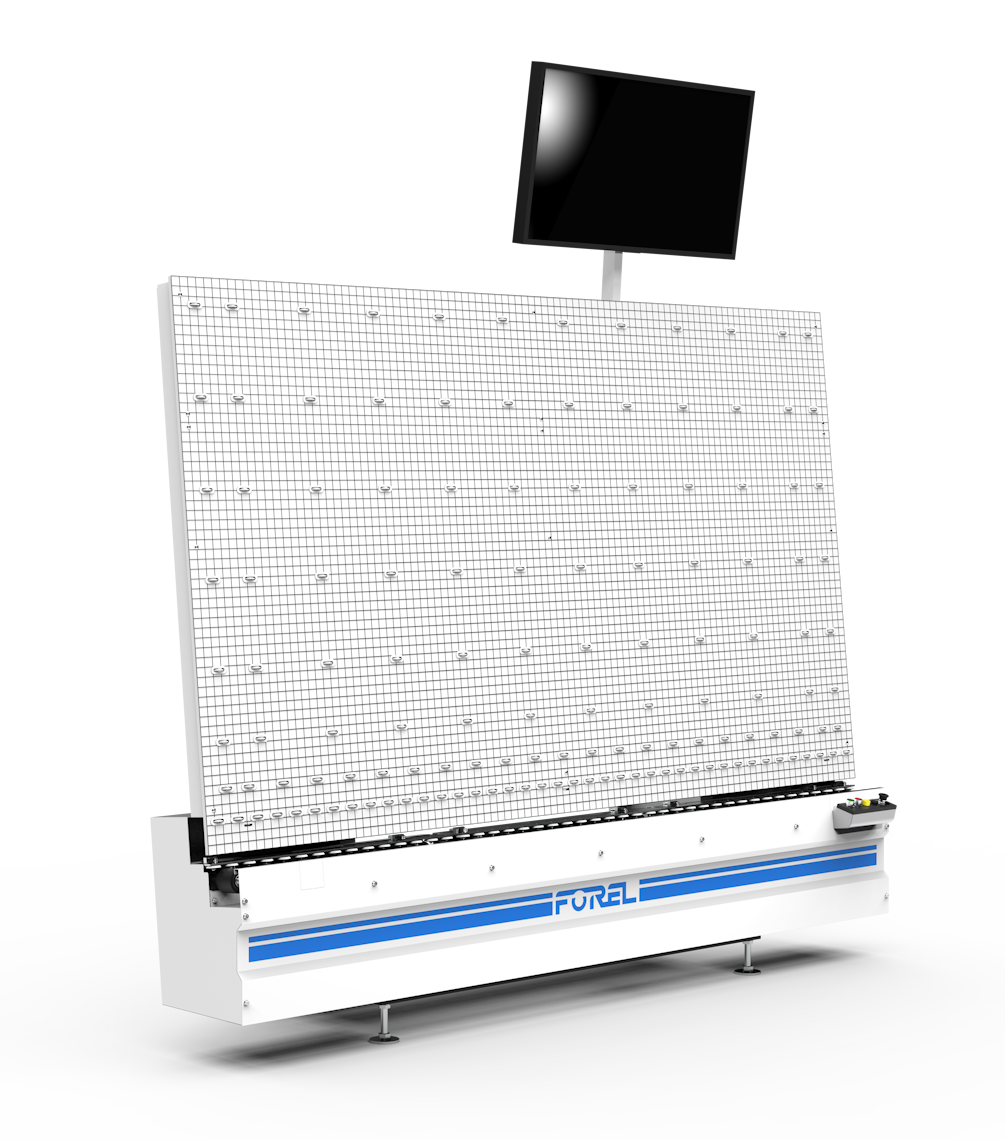

Overall height of the machine body ( mm )

2640

Overall length of the machine body in line ( mm )

3190