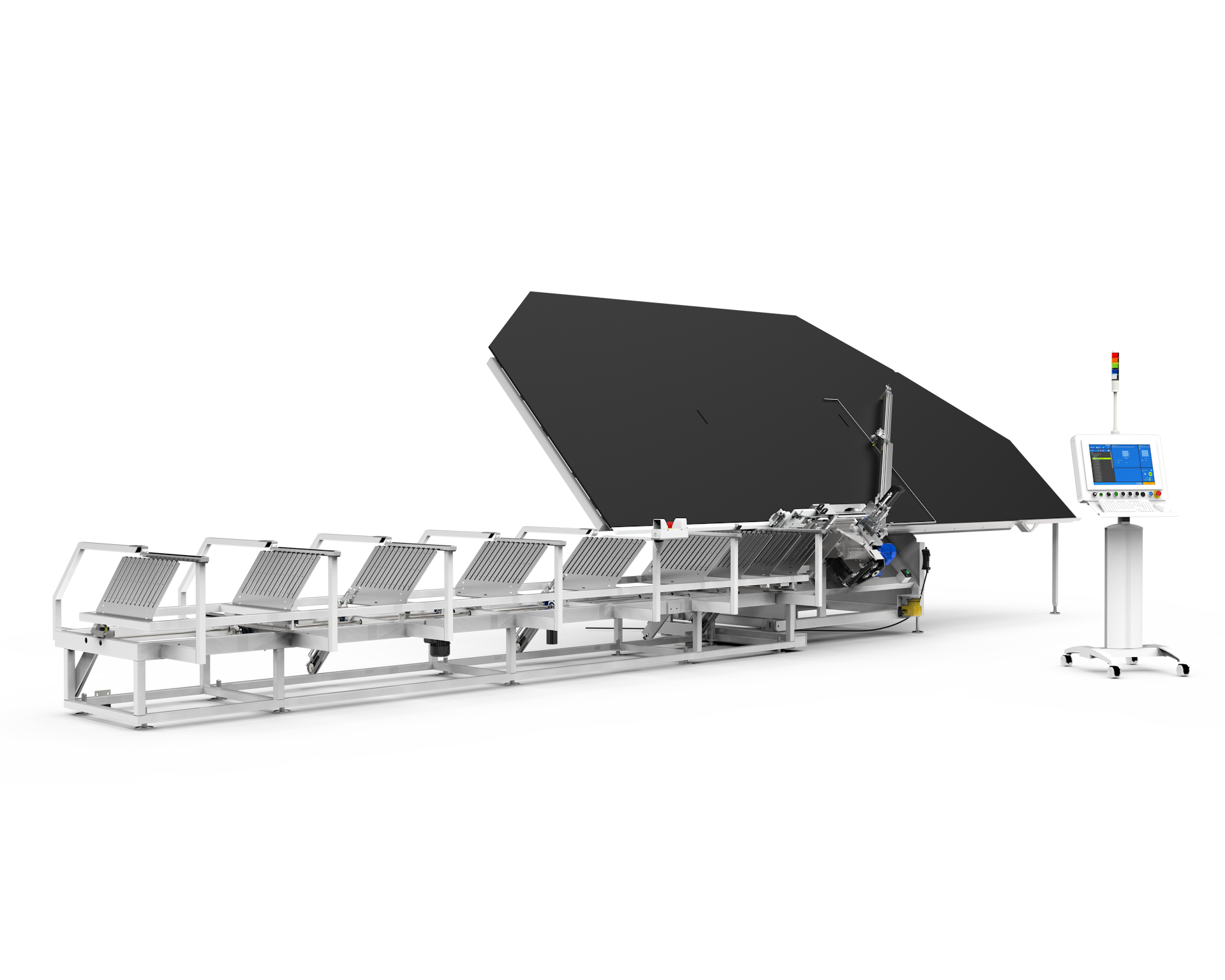

With its patented Smart Arm system, PB HT offers a pioneering solution for the automatic bending of rigid spacer frames, used to manufacture insulating glass units. This robust and versatile machine can bend a wide range of materials, including aluminium, steel, steel/plastic as well as latest-generation spacers in glass-fibre-reinforced plastic. The 12-station storage unit and accompanying arm are designed to optimise frame handling during the process, especially large frames, ensuring precise bending and guaranteeing the integrity of the materials. With a single cutting blade for all types of materials and an automated rotation speed control, PB HT guarantees shear cuts while eliminating the need for lubrication, further simplifying the production process. The machine is equipped with a rapid tool change system and the post-bending side deformation compensation ensures the exceptional quality of the finished frame. Among the available options, laser or ink jet printer.